Volkswagen Sachsen GmbH manufactures three- and four-cylinder gasoline engines with displacements from 1.0 to 1.5 liters at its Chemnitz plant. One assembly line station is dedicated to screwing the fuel rail into place fully automatically, and VW has long been using the Electronic-Key-System EKS from EUCHNER to control access to the assembly workplaces there. Introduced at the engine plant in 2010, the Electronic-Key-System for access control to installations and processes was supplemented with safe selection of operating mode in 2013. In the interest of enhancing operational safety, the plant was recently looking for a way to centrally disable any lost Electronic-Keys in the PLC environment as well. VW found the solution by integrating the EKS Data Service software.

RFID-based EKS access control system

EUCHNER’s Electronic-Key-System EKS consists of Electronic-Keys with writable RFID transponder for user logon to the machine and a control-panel-mounted Electronic-Key adapter into which the Electronic-Keys are placed during machine operation. Each user is issued a personalized EKS Electronic-Key with their specific access rights. In addition to the employee identification number, the information on each Electronic-Key includes the user’s access rights to their working area and scope of responsibilities, as well as their authorization level for using a specific operating mode.

Inserting the EKS Electronic-Key just once puts all functions at the users’ fingertips

The EKS is highly convenient to use: All enabled functions become available as soon as an employee inserts their personalized EKS Electronic-Key into the Electronic-Key adapter on the control panel. Constantly removing, reinserting or changing EKS Electronic-Keys or using key-operated rotary switches is a thing of the past.

Personalized access rights enhance safety

Personalized EKS Electronic-Keys ensure that only authorized and trained users are allowed to change important process parameters on the machine control system. Moreover, the EKS indirectly contributes to enhancing personnel protection by permitting only specially trained personnel to operate the machine in special operating modes. An example of this is a mode for sensitive setup and servicing with an open guard, which could endanger unqualified operators.

EKS Electronic-Key enables operating modes

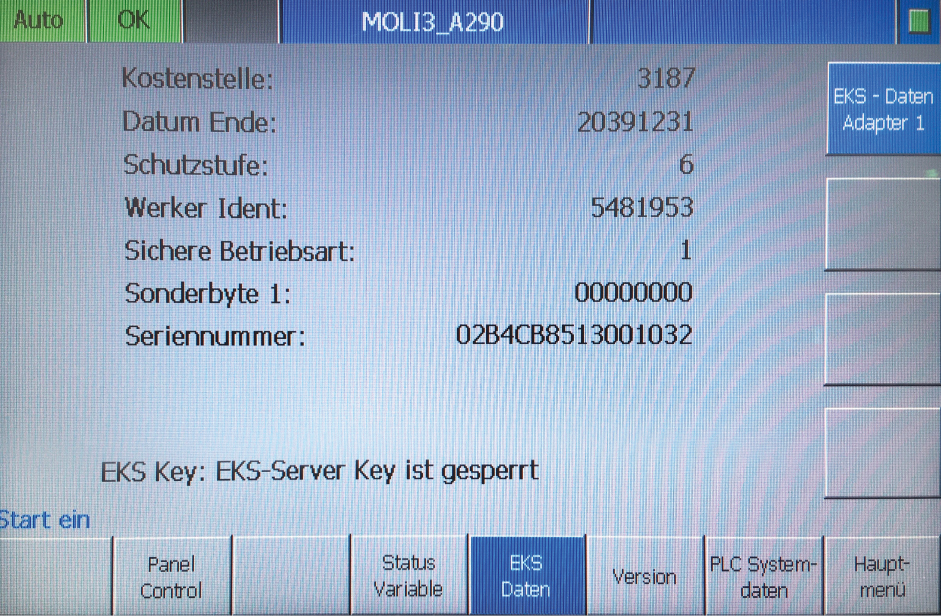

Safe operating modes are enabled via EKS Electronic-Keys at VW Chemnitz. All equipment and robot movements can be set up with the safety door open using a special operating mode in the special fuel rail station, the first station at the Chemnitz plant to operate exclusively with electric drives. The system for selecting the safe operating mode was integrated into the machine’s control panel keypad on this station. Once the employee provides identification via their EKS Electronic-Key, various pushbuttons illuminate on the control panel to allow the authorized operator to select and switch the required operating mode.

EKS Data Service software enhances convenience

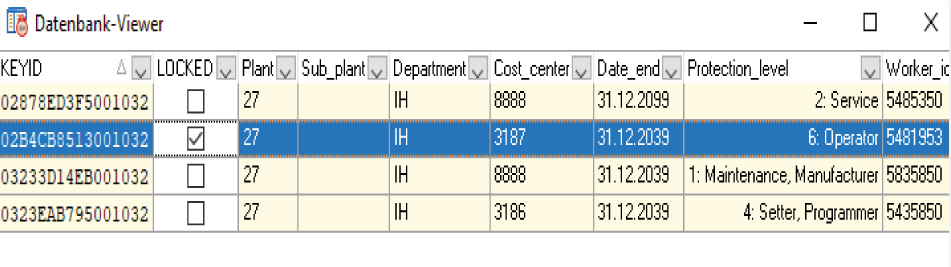

The crucial access information was previously saved exclusively on the respective EKS Electronic-Key when used on the PLC. This had a drawback: A lost Electronic-Key could still be used, which limited protection against potential tampering and misuse. VW Chemnitz has now improved operational safety by adding the versatile EKS Data Service software to link PCs and PLCs. This software can be retrofitted in any existing EKS environment involving Siemens PLC control systems connected via EKS PROFINET or EKS PROFIBUS. The important assembly line access information is now saved both on the EKS Electronic-Key and in the Electronic-Key-Manager EKM database. In practical terms, this means that the read station automatically checks the content and validity of each EKS Electronic-Key. For this purpose, the EKM database contents are exported as a CSV file to the PC environment and then provided to the PLC control system by the EKS Data Service software. EKS Electronic-Keys are usable as soon as they have been positively identified. A lost EKS Electronic-Key can be disabled quickly and easily via the EKM Electronic-Key database. This virtually rules out unauthorized machine access.

|

|

|

More safety for people and processes

Using the EKS and the new EKS Data Service software allowed VW Chemnitz to boost workplace safety considerably. Another advantage is more effective protection against unauthorized or unintentional interventions in the production and assembly process. The EKS thus plays a crucial role in safeguarding the production site’s productivity and quality. The engine plant is now planning to compare individual database elements with the Electronic-Key data for even more effective protection against tampering and misuse.

All EKS advantages for VW Chemnitz at a glance:

- Users are issued personalized EKS Electronic-Keys with their individual access rights and authorizations for selection of operating mode.

- Simply placing the EKS Electronic-Key once makes all enabled functions available. Constantly removing, reinserting or changing EKS Electronic-Keys is a thing of the past.

- Access security to the system is considerably higher than with key-operated rotary switches.

- Lost EKS Electronic-Keys can be disabled quickly.